Hints for techs using the old Dick Smith ESR meter

A lot of this

info also

applies to the current Blue ESR meter from Anatek

Click

here if your newly-built meter's not working properly.

Click

here

if you don't have a variable DC power supply to set up VR1.

New ESR meter users and the front panel chart...

People regularly ask me for more specific ESR figures and for

figures relating to caps not shown on the front panel chart.

The chart is really only

meant to be a rough guide to

what to expect until you get used to ESR measurements you'll encounter

in repair situations, and here's part of an e-mail I recently sent in

reply to these questions, which I hope explains this a bit more clearly:

Once you've been using the meter

for a while and get

used to the kinds of readings you get from electrolytic caps, you'll

see that there's quite a large amount of variability in the figures

you'll get. ESR varies between manufacturers and different capacitor

types, such as normal and high temperature-rated caps. ESR also varies

with ambient temperature. What this means is that if you encounter a

cap not shown on the front panel chart, all you really need to do is

mentally go for the average of the figures of the caps which are shown

on either side of it.

I expect this is giving you the

feeling that it's going

to be impossible to know whether the cap you're checking is good or

not. In fact in my own experience and that of lots of techs I've heard

from, when a cap's ESR is high enough to cause a problem, it will

generally measure at least 10 times the value on

the chart, and more commonly 30+ times the chart value

or give no reading at all. Sick electrolytic caps usually stand out

really clearly.

I don't have a lot more ESR

information, but if you want

to find data sheets on specific electrolytic caps, Doug Jones has a

page of links on his Capacitor

Wizard website which should be helpful to you [Thanks,

Doug!!]. I hope this has better explained the situation with

ESR figures....

Caution... not all

electrolytic caps fail due to high ESR or leakage.

Kevin of Kevin's TV Repair gave this important warning:

"Your

ESR meter sometimes misses caps that show a good ESR reading, but have

a capacitance value of half or less of what they should be. This has

only happened twice, but I rely so heavily on your ESR meter that I

drove myself crazy trying to find the problem elsewhere! Now I know if

everything checks out OK, to pull the caps out of circuit and measure

their value."

I've heard of this happening maybe

3 times to other

techs, so please keep it in mind if nothing seems to make sense, that

the ESR meter might be getting fooled by one of these very unusual

caps.

Now here's the current list of hints. If you

have any handy suggestions I can put on this page, please E-MAIL ME

(1) The way to hold the 9V alkaline battery in place (in the Mk1

meter) is to lay it in the bottom of the case and place a

suitable-sized piece of thick foam plastic over it. Then the circuit

board will hold it snugly in place when the front panel is screwed

down. Dick Smith Electronics now includes a piece of foam in the kits

for this purpose.

Alternately, Andy

in Perth West Australia said:

"Use double sided tape (as I have) to secure the battery. Place 2

strips of tape on the battery on adjacent sides, then press into place

against the bottom and one side of the box. A semi permanent fix, which

allows fairly easy removal, but no major modifications."

Or as Deane McIntyre

suggested: "I found that the

small cardboard boxes that pilot lights come in (boxes of ten 47's for

example) are the exact size to contain the battery and to fit snuggly

into the enclosure under the board."

(2) The "Approximate worst ESR

values" table on the

front of the meter were taken from a fairly old capacitor catalog, and

capacitor technology has evolved a bit since then. For example, many

105ēC electrolytics have an ESR up to nearly double those values even

when brand new, and other electrolytics have a lower ESR even when old.

From my experience if an electrolytic has an ESR more than double the

table value for its capacitance and voltage rating, it's wise to check

it against a new one and/or replace it to remove the chance of it

causing problems in the future.

The best way to be

confident about whether a suspect

capacitor is good or not is to measure the ESR of one or more brand-new

ones of the same value and working voltage!

(3) Hank Sievers

said, "Bob

Parker's meter can also be used as a go-no go type. I have found that I

can consider everything below 3 ohms as good, and all over 10 as bad,

with very few falling in the doubtful category'. I agree that except

for very large and very small caps, this is a useful 'rule of thumb'".

Thanks, Hank!

(4) The "DISCHARGE CAPACITOR

BEFORE MEASURING!" warning on the meter front panel is a little

over-cautious.... "Test only discharged capacitors!"

would have been better. Nearly all electrolytics are discharged by

their surrounding circuitry within a few seconds of the power being

disconnected, so you can generally poke around with the meter without

worrying about this. The only caps which are likely to need deliberate

discharging are the main filters in amplifiers and other large power

supplies.

(5) Glenn Watkins

has pointed out that a shorted

or partially shorted cap can check OK (ie: low resistance), so if you

check a cap and the indicated ESR seems too good (low) to be true, it's

wise to check it out with an ohm meter. Or you can parallel the ESR

meter and an ohm meter and look for shorts at the same time... see #13

below.

(6) Glenn also

said, "It's very hard to press the

test lead tips together to get a steady reading before pressing the

button to zero the display. I found that if the test leads have sharp

tips, you can press them both on a solder pad (on a PC board) and the

leads will penetrate the solder a little giving a good solid reading".

Thanks Glenn!

(7) David aka

'Starwriter' provided this

alternative way of shorting the test leads: "To zero the meter, I poke

the probe tips into 1 of the philips screws on the front of the case.

It's easy to hold the leads together this way while you push the

button." Good idea and thank you kindly, David!

(8) The meter puts out regular

bursts of 10us pulses at

a 2KHz rate, at an open-circuit amplitude of about 600mV P-P. At a

pinch you can use it as an audio signal source to check speakers,

amplifiers etc. The pulses have a fast rise/fall time, so it would

probably make a crude RF signal injector as well. Thanks to 'Kiwi'

Joe Lussy for suggesting this!

(9) Varying contact resistance

between the banana plugs

and sockets can cause unsteady readings, but if you give each plug a

big squirt of CRC "CO Contact Cleaner" then rapidly jiggle it in its

socket for a few seconds, this reduces the problem considerably. Also

be aware that the nuts holding the banana sockets can work

themselves loose

over time, causing a variable and gradually increasing indicated test

lead resistance... this happened on my own prototype meter and others

I've heard about.

(10) If you'd like to get more

battery life out the

meter (and are feeling a bit adventurous), you can replace IC1 (78L05)

with an LP2950CZ-5.0 and replace R25 (47k) with 27k.

Then adjust VR1 so the low battery warning triggers at 5.6V

instead of the original 7.0V. Thanks to G. Freeman

in South Australia for this idea which was published in the August '98

issue of Electronics Australia magazine.

Note: When using the MK2

ESR meter's self-test function after doing this modification, it will

need to be powered from 6.2 - 6.8V, not 9V as it

originally was.

(11) Mark Stevenson

has devised some ingenious methods of installing a 'Low Ohms'

buzzer in the ESR meter, which make it less necessary to

watch the displays while you're using it. Click here

to get his instructions on how to do it, as a text file. And click

here for the schematic. Thanks for that, Mark!

(12) I haven't tried it myself,

but I've heard from

several sources that the ESR meter is quite good at indicating the

condition of batteries of both the normal and rechargeable kind. Click

here to visit the John's Jukes website where John

Robertson has some information about this.

(13) John Robertson

also made this handy

suggestion which should work OK: "I thought you might want to modify

your ESR meter hints page to have folks try out my use of the ESR meter

and a regular Ohm-meter in parallel to find those pesky shorted caps. I

found that the cheap shop digital meter worked just fine and using its

low ohm beeper function finds the shorts!". Thanks again, John!

(14) Col Hardy

said: "Love the meter, but had a few quirks with the banana sockets

provided. I soldered a twin cable to the the PCB terminals and ran it

out of one of the sockets, soldered sewing pins to the wires, works

great. To increase battery life 20 fold, cut the track from the display

mplex emitters (Q12/13) and add a resistor in series. I used a 500 ohm,

so a 470 or 390 would be good starting points. Battery life is extended

from a few weeks to 6 months or so (though the displays are dimmer)."

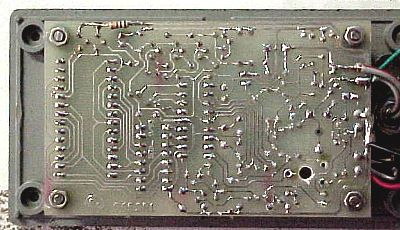

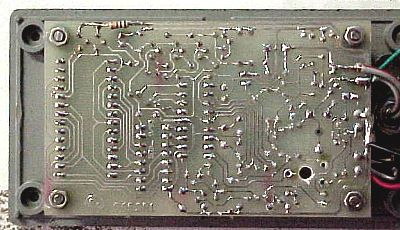

Col's extra resistor

is in the top left corner of his meter

board here.

Thanks, Col!

(14) Col Hardy

said: "Love the meter, but had a few quirks with the banana sockets

provided. I soldered a twin cable to the the PCB terminals and ran it

out of one of the sockets, soldered sewing pins to the wires, works

great. To increase battery life 20 fold, cut the track from the display

mplex emitters (Q12/13) and add a resistor in series. I used a 500 ohm,

so a 470 or 390 would be good starting points. Battery life is extended

from a few weeks to 6 months or so (though the displays are dimmer)."

Col's extra resistor

is in the top left corner of his meter

board here.

Thanks, Col!

(15) Mike (Moby) Diack

made this useful

suggestion: "Haven't needed to test a single cap yet, but (being a

fixer of big PA amps) it's just fine for 1/ Finding a punched through

transistor in a big parallel bank and 2/ Finding a crook bypass cap

amongst dozens between +5 and gnd." I hadn't thought of that, so thanks

Mike!

(16) If you're swapping between

powering the meter from

a battery and an external 9V DC power supply, there's a little

modification you can do which disables the meter's automatic switch-off

function when running from the power supply. Click here

for the circuit as a .gif file. The extra NPN transistor can be any

small-signal one, such as BC548 etc. Dave Burla

assures me that it does work!

(17) ESR meter

carry case! Tom Chipman

recommended: "I purchased a case at Walmart for $8.88. Look in the

Women's purse section. It is actually some type of makeup case,

configured in the form of a miniature footlocker, but without a tray,

just a rectangular box with a lining. It is just the right size to

accomodate the meter, with enough room to tuck the leads along side.

Because it is rigid, there is no danger of transferring the on/off/zero

switch, when the case is closed, or handling it." Thanks Tom, it sounds

like a great idea!!

(18) Stop the push button from being bumped in your

toolbox...

Ricky Lee Ponder sent this idea and excellent photo

to

illustrate it: "I have a little tip for people who might want to carry

this in a toolbox or bag. I got concerned that something would always

be pushing the button. So I took a plastic housing off of a D.C. barrel

plug and it slides right down over the red button and threads onto the

switch threads. This prevents anything from pushing the button until

you take it off. I did have to leave the lock washer off so enough

threads remained for the cover to thread on to."

- Or you could try -

Mark Twitchell [N2WAE] had this similar thought:

"Something I

was going to try with the ESR meter is to put a washed out cap (note- I

mean a CAP, as in bottle cap, not capacitor) from a spent tube of lip

balm (Chapstik, Blistex, etc.) on the power switch button. Make sure

that the cap is plastic, NOT metal. You can try and cut or punch a

clean hole in the center of the bottom to pass the power switch

threaded shaft, and then screw down the nut using long nose pliers, to

protect the switch from being pushed accidentally in your pocket or

tool kit (may keep the battery fresh longer). If the cap is too tall,

try putting it back on the original container, and cutting it around

with a razor knife at the lower height and re-fit it."

- Or this -

Bob Ecclestone did it

this simple way: "I also

had problems with the first unit switching on in the toolbag and I

glued a tube cap over the switch, but this caught on other things in

the bag. So on the second unit, I cut the button off the switch stem

and filed the stem down so it was just below the switch body when

pushed in. Now the switch does not turn the unit on if inadvertently

bumped in the bag, but it is still quite easy to turn it on."

Thanks, guys!

(19)

From Iain Emerson:

"Like Col Hardy I too had a problem with the test leads on loose caps.

Fixing a small piece of PCB (two pads) just above the display and

connecting them to the terminals through the casing allowed the leads

of a cap to be placed directly on the pads and tested, and it's also a

quick way to zero the meter with just one hand free."

(19)

From Iain Emerson:

"Like Col Hardy I too had a problem with the test leads on loose caps.

Fixing a small piece of PCB (two pads) just above the display and

connecting them to the terminals through the casing allowed the leads

of a cap to be placed directly on the pads and tested, and it's also a

quick way to zero the meter with just one hand free."

The pad measures 40mm x 8mm with a 3mm gap

(copper

removed with a craft knife) half way along. The pad sits on a 5mm thick

piece of foam rubber held in place by two-sided sticky tape. Two 2mm

holes were then drilled in the front panel for the leads that are

soldered to the two test lead sockets and pads respectively ie; left

pad, left socket etc.... Thanks Iain!

(20) Alastair MacGregor has found that the ESR

meter can identify suspect inductors... "If an inductor has shorted

turns it loses inductance but may maintain resistance. So if I have a

line drive transformer for example, I can stick the ESR meter across

it. If get a reading, the transformer has shorted turns or should be

investigated more."

Choong Keat Yian

added that he tests small

transformers such as TV deflection and SMPS power supply ones by first

measuring their DC resistance with his Fluke 12 DMM. If he sees a very

low resistance (maybe 0.3 ohms), next he connects the ESR meter to it.

If the ESR meter doesn't show "- " (more than 99

ohms), it

almost certainly means that the inductor has shorted turns. He said,

"Best of all, all this can be done while onboard without desoldering in

most cases".

(21) 'DICK SMITH' TIP by Joe Sopko, writing for "THE

SPEAKER", the newsletter of NesdaOhio.

"After

a couple years of use, I just had

the first

failure of my prized 'Dick Smith' ESR Meter. Other owners know that

when you use the meter, the first press of the push button switch turns

it on, then you put the probes together & the second press of

the

switch subtracts the resistance of the meter leads from the display

& 'zeros' the meter. Well, my failure was that the second press

turned it off - instead of zeroing the display. Bummer! How can you use

a meter that turns itself off when you go to use it? That makes it just

as bad as an employee! At least MY employees tend to turn themselves

off when I go to use them. The cure was simple - if you know it. I wish

I would have known this before I disassembled the meter &

looked

for a problem that wasn't internal. Over the years, the probes had

slowly built up a slight coating of oxidation. They still looked bright

& shiny, but in fact when I put them together, they were

reading

about 2.1 ohms. That was enough to tell the meter that the probes were

NOT together and to shut off the meter on the second press. The cure? A

quick wipe of the probes & jacks with tuner cleaner. Problem

solved! It made me so happy I just had to grab a SMPS & measure

some caps." Thank you, Joe!

"After

a couple years of use, I just had

the first

failure of my prized 'Dick Smith' ESR Meter. Other owners know that

when you use the meter, the first press of the push button switch turns

it on, then you put the probes together & the second press of

the

switch subtracts the resistance of the meter leads from the display

& 'zeros' the meter. Well, my failure was that the second press

turned it off - instead of zeroing the display. Bummer! How can you use

a meter that turns itself off when you go to use it? That makes it just

as bad as an employee! At least MY employees tend to turn themselves

off when I go to use them. The cure was simple - if you know it. I wish

I would have known this before I disassembled the meter &

looked

for a problem that wasn't internal. Over the years, the probes had

slowly built up a slight coating of oxidation. They still looked bright

& shiny, but in fact when I put them together, they were

reading

about 2.1 ohms. That was enough to tell the meter that the probes were

NOT together and to shut off the meter on the second press. The cure? A

quick wipe of the probes & jacks with tuner cleaner. Problem

solved! It made me so happy I just had to grab a SMPS & measure

some caps." Thank you, Joe!

(22) Brian Gerber C.E.T. said: "Most techs know

they can sometimes find a faulty cap with a can of freeze spray. If you

have a cap that the ESR is say marginal, it still may not perform under

a load condition until it warms up. I have found if you have this

condition and you freeze all the caps and recheck with the ESR meter,

they stick out like a sore thumb!!!" Good idea, Brian. :-)

(23) Tony Marsillo (Nutmeg Repair) gave us this

useful advice: "For measuring caps in circuit using one hand I

purchased a set of Tweezer

Probes from MCM electronics, part number 76-001.

The tips are such that they can be shorted together to zero the meter.

Don't get the Pomona type, their tips do not touch when squeezed

together. I have been using the meter for about 2 years and it has

saved me quite a lot of time. Thanks."

Thank you too, Tony!

However, as Richard Sato suggested, if you're

good at using chopsticks then you don't really need tweezer probes.

Just hold the normal probes in the same way. It's surprisingly easy

once you get used to it. I've been doing this for years.

(24) Peter Morgan found yet another use for the

meter: "Had occasion to have to trace out the schematic of a board

which had numerous tracks/vias under the chips - a real PITA.

Eventually (an hour or more) I had a hand-drawn schematic. Now to

verify ... I remembered that the ESR meter pulses are below the

threshold of diode junction conduction, so I proceeded to use it as a

yes/no check of every pin to every other. Must have been all of five

minutes and all permutations had been tested. I'm probably not the

first to use it in this way, but it is another use for this great

device."

Maybe not the first,

but the first I've been told about.

Thanks for sharing your idea with everyone, Peter. :-)

(25) John Robertson at John's Jukes noticed an

old article about problems caused by poor grounding in tube guitar

amplifiers and commented that the ESR meter is very good at locating

bad connections. So there's another use for it. :-)

Upgrade your displays!

LED

display technology has improved a lot in the decades since the Dick

Smith ESR meters came out.

Kiel Lydestad said, "I replaced the displays with a pair of Lite-On LSHD-5503 red 17mcd modules.

What a difference!" and sent me this photo to prove it...

Extra protection diodes

Quite a lot of people are installing a pair of 1N5404 or similar high

current diodes in inverse parallel across the test lead jacks/sockets,

to give more protection if the meter's connected to a large charged

capacitor. So far I haven't heard of any meters being damaged after

this modification, though it's not good for the test lead probes, the

diodes or the capacitor.

Remember that you cannot test the ESR of batteries

after installing these diodes!

Stan Labinsky Jr

provided these nice photos of his installation, which is the best

& neatest I've seen. Thanks again Stan!

Jacques Carrier's "new" ESR meter.

---------------------------------

Upon reading your article about the new version of your ESR meter I finally decided to

tune-up my ESR meter.

After using it for about 3 years, it was time to finally remove a few annoyances:

1) I desoldered R25 to disable the 2 min. auto shut-off function. Great! No more powering up to do.

Time saver too.

2) I also installed 2 diodes (1N5404) across the inputs. It is so tight inside the meter......... no problem----- I simply

put them outside........ (They are mounted on a stackable banana plug in which the output leads are inserted.) It does

not look too bad and you do not have to open the case if you have to replace them. Great protection for this priceless

meter!

3) I removed the battery (power hungry meter)!!! Expensive 9V Duracell battery eliminated.

I installed a small 9VDC adapter (13 VDC unloaded) followed by an in-line 7808 regulator (mounted inside a plastic fuse

box).

I left the battery connector inside (properly insulated) just in case I ever need to use the battery again.

The adapter is connected to the meter through a small polarized male/female connector.

The ESR meter is now much user friendly (....for me). I am madly in love with my "new" meter!!!!

Graphs... Graphs... Graphs...!!

Matt Warren has created some graphs of typical new capacitor

value vs working voltage vs ESR

which are interesting in their own right and also great for working out

values in between those in the meter's front-panel chart. Just click on

the following links to get them:

Graph

#1

Graph

#2

Graph

#3

And if you own another ESR meter such as Doug Jones' highly respected Capacitor

Wizard

and would like a copy of the chart of approximate worst-case ESR

figures from the front of my meter for reference, CLICK HERE

to download one as a text file, or HERE as a .pdf

file you can print out!

Thanks to M Davis

for suggesting I make this

available!

And now the answer to the question 'everyone' is asking... Why

does the original "Mark 1" meter flash 'EA' at switch-on? Answer:

'EA' stands for 'Electronics Australia',

the magazine this meter appeared in as a construction project, back in

January 1996. Sadly this magazine no longer exists. The "Mark 2" and Blue ESR meters don't do this.

Finally a big 'THANK YOU' to all you techs who've bought this

meter

kit and said good things about (and constructively criticised) it, both

on the sci.electronics.repair newsgroup and to me directly. I really

appreciate it!

Back to the ESR meter

page...

Back

to the home page...

Last update: 21 July, 2024

(14) Col Hardy

said: "Love the meter, but had a few quirks with the banana sockets

provided. I soldered a twin cable to the the PCB terminals and ran it

out of one of the sockets, soldered sewing pins to the wires, works

great. To increase battery life 20 fold, cut the track from the display

mplex emitters (Q12/13) and add a resistor in series. I used a 500 ohm,

so a 470 or 390 would be good starting points. Battery life is extended

from a few weeks to 6 months or so (though the displays are dimmer)."

Col's extra resistor

is in the top left corner of his meter

board here.

Thanks, Col!

(14) Col Hardy

said: "Love the meter, but had a few quirks with the banana sockets

provided. I soldered a twin cable to the the PCB terminals and ran it

out of one of the sockets, soldered sewing pins to the wires, works

great. To increase battery life 20 fold, cut the track from the display

mplex emitters (Q12/13) and add a resistor in series. I used a 500 ohm,

so a 470 or 390 would be good starting points. Battery life is extended

from a few weeks to 6 months or so (though the displays are dimmer)."

Col's extra resistor

is in the top left corner of his meter

board here.

Thanks, Col!

(19)

From Iain Emerson:

"Like Col Hardy I too had a problem with the test leads on loose caps.

Fixing a small piece of PCB (two pads) just above the display and

connecting them to the terminals through the casing allowed the leads

of a cap to be placed directly on the pads and tested, and it's also a

quick way to zero the meter with just one hand free."

(19)

From Iain Emerson:

"Like Col Hardy I too had a problem with the test leads on loose caps.

Fixing a small piece of PCB (two pads) just above the display and

connecting them to the terminals through the casing allowed the leads

of a cap to be placed directly on the pads and tested, and it's also a

quick way to zero the meter with just one hand free."

"After

a couple years of use, I just had

the first

failure of my prized 'Dick Smith' ESR Meter. Other owners know that

when you use the meter, the first press of the push button switch turns

it on, then you put the probes together & the second press of

the

switch subtracts the resistance of the meter leads from the display

& 'zeros' the meter. Well, my failure was that the second press

turned it off - instead of zeroing the display. Bummer! How can you use

a meter that turns itself off when you go to use it? That makes it just

as bad as an employee! At least MY employees tend to turn themselves

off when I go to use them. The cure was simple - if you know it. I wish

I would have known this before I disassembled the meter &

looked

for a problem that wasn't internal. Over the years, the probes had

slowly built up a slight coating of oxidation. They still looked bright

& shiny, but in fact when I put them together, they were

reading

about 2.1 ohms. That was enough to tell the meter that the probes were

NOT together and to shut off the meter on the second press. The cure? A

quick wipe of the probes & jacks with tuner cleaner. Problem

solved! It made me so happy I just had to grab a SMPS & measure

some caps." Thank you, Joe!

"After

a couple years of use, I just had

the first

failure of my prized 'Dick Smith' ESR Meter. Other owners know that

when you use the meter, the first press of the push button switch turns

it on, then you put the probes together & the second press of

the

switch subtracts the resistance of the meter leads from the display

& 'zeros' the meter. Well, my failure was that the second press

turned it off - instead of zeroing the display. Bummer! How can you use

a meter that turns itself off when you go to use it? That makes it just

as bad as an employee! At least MY employees tend to turn themselves

off when I go to use them. The cure was simple - if you know it. I wish

I would have known this before I disassembled the meter &

looked

for a problem that wasn't internal. Over the years, the probes had

slowly built up a slight coating of oxidation. They still looked bright

& shiny, but in fact when I put them together, they were

reading

about 2.1 ohms. That was enough to tell the meter that the probes were

NOT together and to shut off the meter on the second press. The cure? A

quick wipe of the probes & jacks with tuner cleaner. Problem

solved! It made me so happy I just had to grab a SMPS & measure

some caps." Thank you, Joe!